- Stock: In Stock

- Model: ST22008049

- SKU: ST22008049

Features:

Product name:Plastic Welding Gun

The welding gun operation can be performed without air pump and the regulating transformer, easy to use

Applicable to: Plastic Welding

Specification:

Material: Steel, Plastic

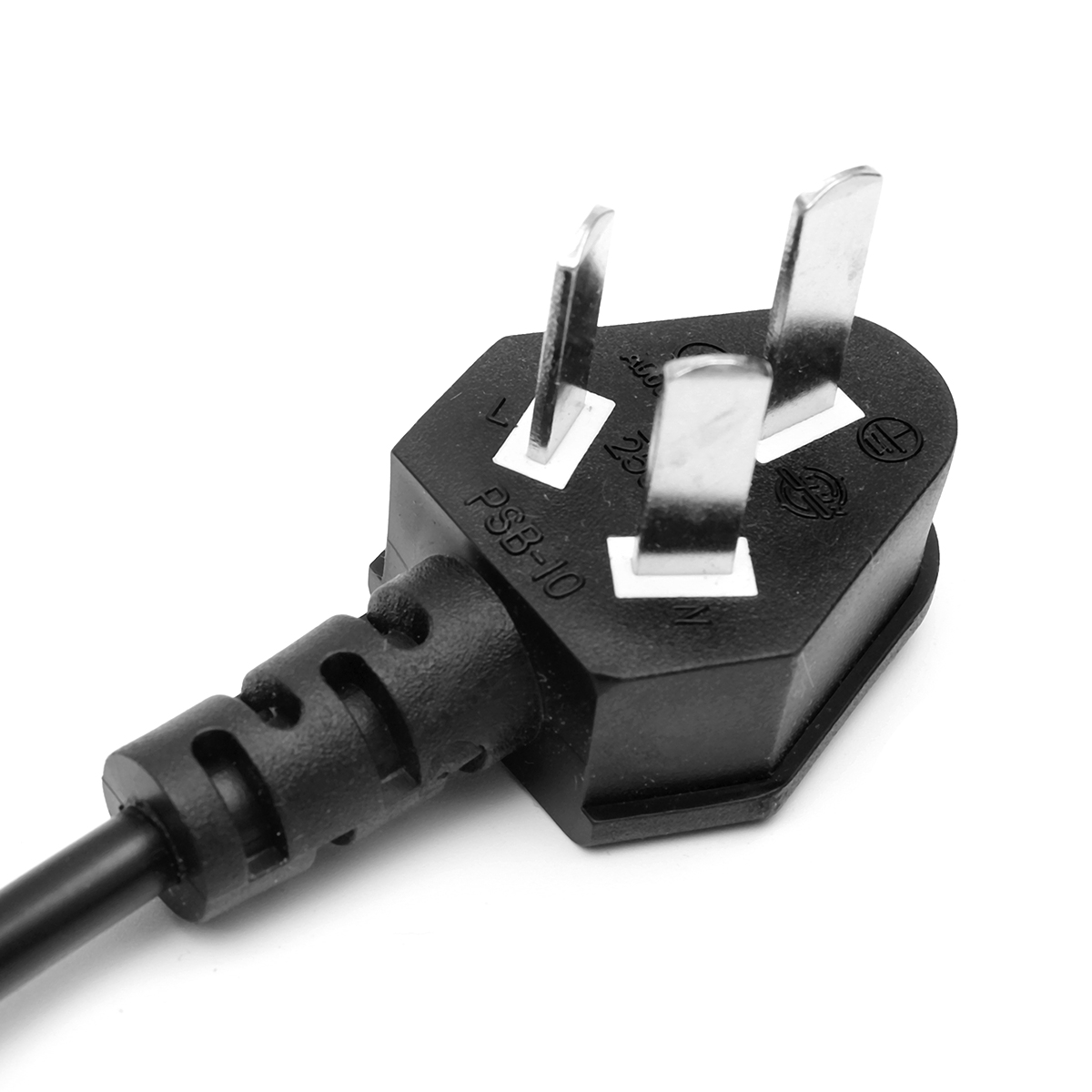

Voltage: AC 220-240V

Motor Voltage: DC 24V

Power: 700 W

Temperature: 100 ° C to 450 ° C

Function: hot air

Size: 22 x 15cm (8.7" x 6")

Mouth hole Inner Diameter: 5.8MM 0.2"

Mouth hole Outer Diameter: 8.2MM 0.3"

Package Included:

1 x Welding Gun

1 x Ceramic heater

How to use:

1. Turn on the thermostat switch on the handle. Turn the power to the right after turning on the "snapped" sound. Turn the green indicator light to the left, then turn on the cold wind and turn on the red indicator lamp. Hot air, until the screw does not move, the temperature reached the highest.

2. Use the process, according to the need to timely adjust the temperature, and pay attention to the distance between the nozzle and the solder joint to achieve the desired welding requirements.

3. This may be normal when you smoke or smoke the Mars for the first time. Automatically disappear after a few seconds.

4. Use should keep the tail of the gun into the wind smoothly, otherwise, will lead to fever overheating burned.

5. After the welding is completed, turn the switch to the cold windshield (both after the red light goes out), send cold air for a while, so that steel and heating core cooling down, and then shut down. This will effectively protect the heating wire waste heat is too high after the life of the heating core burned lead. To complete the use of this product light custody, so as not to damage the torch part of the refractory material, resulting in electric wire off.

6. If the heating core burned out, you can unscrew the shell to connect the screw to remove the heating core, do not open the handle, replace the factory with the model of the heating core.

7. Use, must have a ground connection, to ensure safety.

Notice:

1. When you use for the first time, there may be flame or smoke. This is a normal phenomenon,it will disappear after 5 minutes powering on.

2. Plastic sheet is heated to 130-140 degrees for the soft state, with a little pressure molding. The welding temperature is 240 degrees or so commonly, from welding nozzle mouth about 5 to 10 mm at temperature of 200-260 degrees; Should be paid attention to during welding nozzle and the distance between the solder joint. In order to obtain ideal welding temperature.

3. Heating wire break, can be shot and shell connection screw, remove the gun core, with the same specifications of the gun core change.

4. Welding torch with finish to put light, lest broke the gun core part of the refractory porcelain, and make the heating wire short circuit.

5. To turn it off before the temperature should be transferred to the cold wind, blowing a few minutes, after cooling barrel can be turned off.

6. For unavailable, must be connected to ground, in order to protect security.

,

, ,

, ,

, ,

, ,

,