- Stock: In Stock

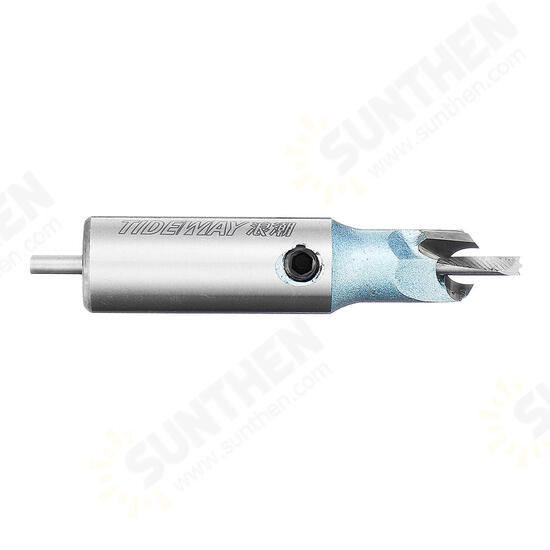

- Model: ST22004445

- SKU: ST22004445

Specification:

| Product grade | Industrial grade |

| Material | Cemented carbide |

| Type | Angle cutter |

| Coating | Yes |

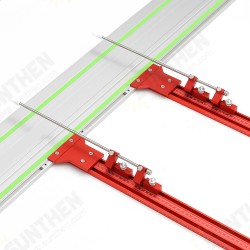

| Suitable for machine tools | Woodworking machine tools |

| Processing range | 0-50mm |

| Diameter | 6mm |

| Cutting thickness | Ф10 |

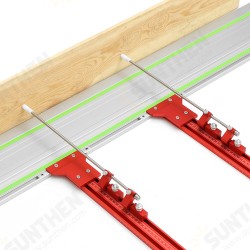

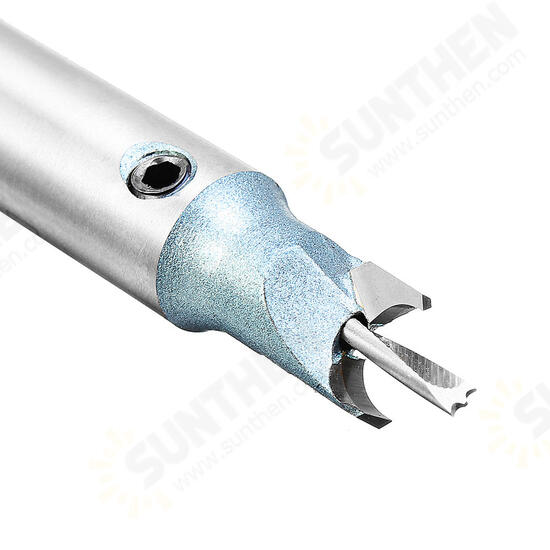

Features: 1. Woodworking lock mill cutter is specially designed for portable or desktop woodworking engraving machine.

2. The cutter can cut smooth surface of hardwood, softwood, composite, board and other materials, and it is more smooth to cut without burrs or burrs.

3. Wide range of applications, such as factory building materials, home shops, carpentry enthusiasts.

4. The blade is made of high quality hard alloy and carefully designed, developed and tested repeatedly, which not only improves the service efficiency,

but also significantly improves the durability and noise reduction.

5. The hilt is made of hard 45 steel. The spiral design is wear-resistant and not aging.

6. New spray coating, wave resistance to high temperature, corrosion and other features, extended service life.

Operation precautions:

(1) Cutting tools can produce smooth surface for wood such as hardwood, softwood and synthetic board, but should avoid processing metal materials such as copper and iron as well as non-wood materials such as sand and stone.

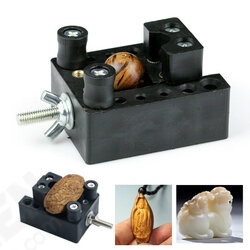

(2) Make sure to use the clamping sleeve of appropriate size, because it is worn seriously, not round enough and with taper of inner bore cannot provide enough clamping strength, which leads to vibration or fly off when the blade handle is broken.

(3) Never assume that the new jacket is safe and reliable.When uneven contact marks or grooves are found in the handle part after clamping, slip situation and inner hole deformation of the clamp should be replaced immediately to avoid accidents.

(4) When the cutter is installed and clamped, stop the machine immediately if it is found that the knife has a fluttering phenomenon when working. Repeat the clamping for several times so that the tool handle and the clamping sleeve are in full contact and the work is carried out.

(5) The tool handle should be in good contact with the clamping sleeve, and the tool handle must be fully inserted into the clamping sleeve and tightened firmly, so as to provide sufficient clamping force for the tool.A small part should not only be inserted into the sleeve, otherwise it may cause breakage of the shank and damage to the cutter.

(6) Appropriate research and ear protection devices should be used during operation.

More Details: